In the dynamic landscape of the electrical equipment industry, manufacturers face a multiple challenges driven by the evolving needs of consumers and regulatory demands. A primary concern is the increasing emphasis on energy efficiency and sustainability, compelling the development of products with lower environmental impact and compliance with stringent regulations. The preference for compact and integrated devices necessitates the creation of smaller, more efficient components without compromising performance, leading to challenges in heat dissipation and reliability.

Ensuring safety standards and regulatory compliance, especially in household electrical equipment, is critical. Competitive markets and cost-conscious consumers drive manufacturers to seek innovative ways to produce high-quality products at lower costs while maintaining compliance. The industry's rapid technological advancements demand continuous research and development efforts to keep pace with the latest technologies, leading to short product life cycles and frequent updates.

The iterative process of designing, prototyping, and testing poses a significant challenge for manufacturers. To address this issue, a solution is needed to speed up product development, troubleshoot more efficiently, gain technical insights, foster new design ideas, and ultimately strengthen competitive edges.

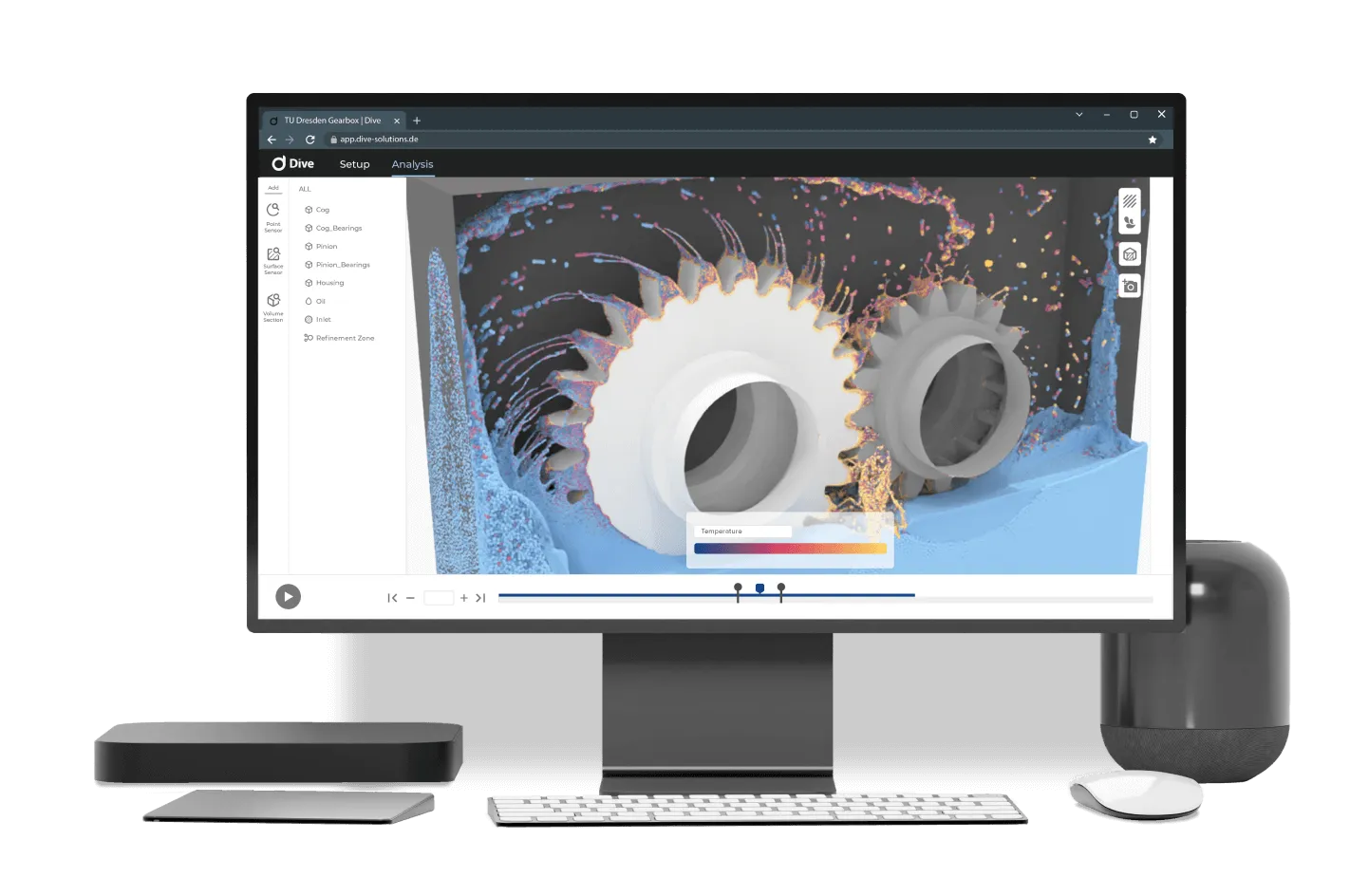

The answer lies in simulation-driven design, which accelerates time-to-market, reduces physical testing, and enables faster and better engineering decisions. This solution helps manufacturers save costs by frontloading design decisions, gaining and sharing valuable technical insights, and testing designs more comprehensively. Utilizing simulation tools efficiently allows design and simulation teams to collaborate seamlessly, empowering design engineers to conduct independent simulation studies while simulation experts focus on complex inquiries and overall modeling quality. This innovative approach addresses the industry's challenges, ensuring a more sustainable and efficient future for electrical equipment manufacturing.

If your engineering team is dealing with liquids and heat management, chances are this is the right software for you.

Use the Dive CFD software, free for a week, including service by a Customer Success Engineer who will ensure successful results for your project. No strings attached. Comfortably evaluate your project before you commit to a subscription.

A Dive representative will contact you, typically within 1 business day. Note: Only registrants with valid use cases will be contacted.