Free your design and simulation team from unnecessary constraints with a simple, fast, and accurate CFD software that every engineer can use. Mesh-free fluid simulation, HPC infrastructure and professional services in one.

Expand your engineering know-how and leverage your competitive edge. Discover the unknown and make important product insights accessible and comprehensible for your colleagues and customers.

Cutting radically on project duration means less time for design optimization or troubleshooting. Minimize the risk of product failure and costly product maintenance. By testing and iterating faster with CFD simulation, your products are more sustainable.

Most simulation solutions require staff with specialized skills, which makes scarce experts the productivity bottlenecks. With a mesh-free technology, user-friendly automation and collaborative workflows, design engineers are empowered to conduct simulation studies independently. This way, simulation experts focus their time on complex inquiries and general modeling quality.

If your engineering team is dealing with liquids and heat management, chances are this is the right software for you.

Use the Dive CFD software, free for a week, including service by a Customer Success Engineer who will ensure successful results for your project. No strings attached. Comfortably evaluate your project before you commit to a subscription.

How you use our service depends on the number of core hours you need throughout the year. Core hours are calculated based on the number of CPU cores running during simulations. To give you an idea, if you run a 40-core CPU for 4 hours, it adds up to 160 core hours. Importantly, you pay for the usage, not per license.

Think of it like choosing a data volume for your smartphone plan – you pick a package size based on your needs. The cost includes our support, hardware, and software, so you can focus on your engineering tasks, and we take care of the rest.

If you want more details on pricing, just reach out to us by booking a Demo, and we'll get back to you shortly.

With our license, it's not just about the tool. You also receive support from our team of CFD experts known as Customer Success Engineers. They don't just guide you through troubleshooting; they share their knowledge and best practices to help you optimize the setup, reduce costs, and enhance the performance of your computations.

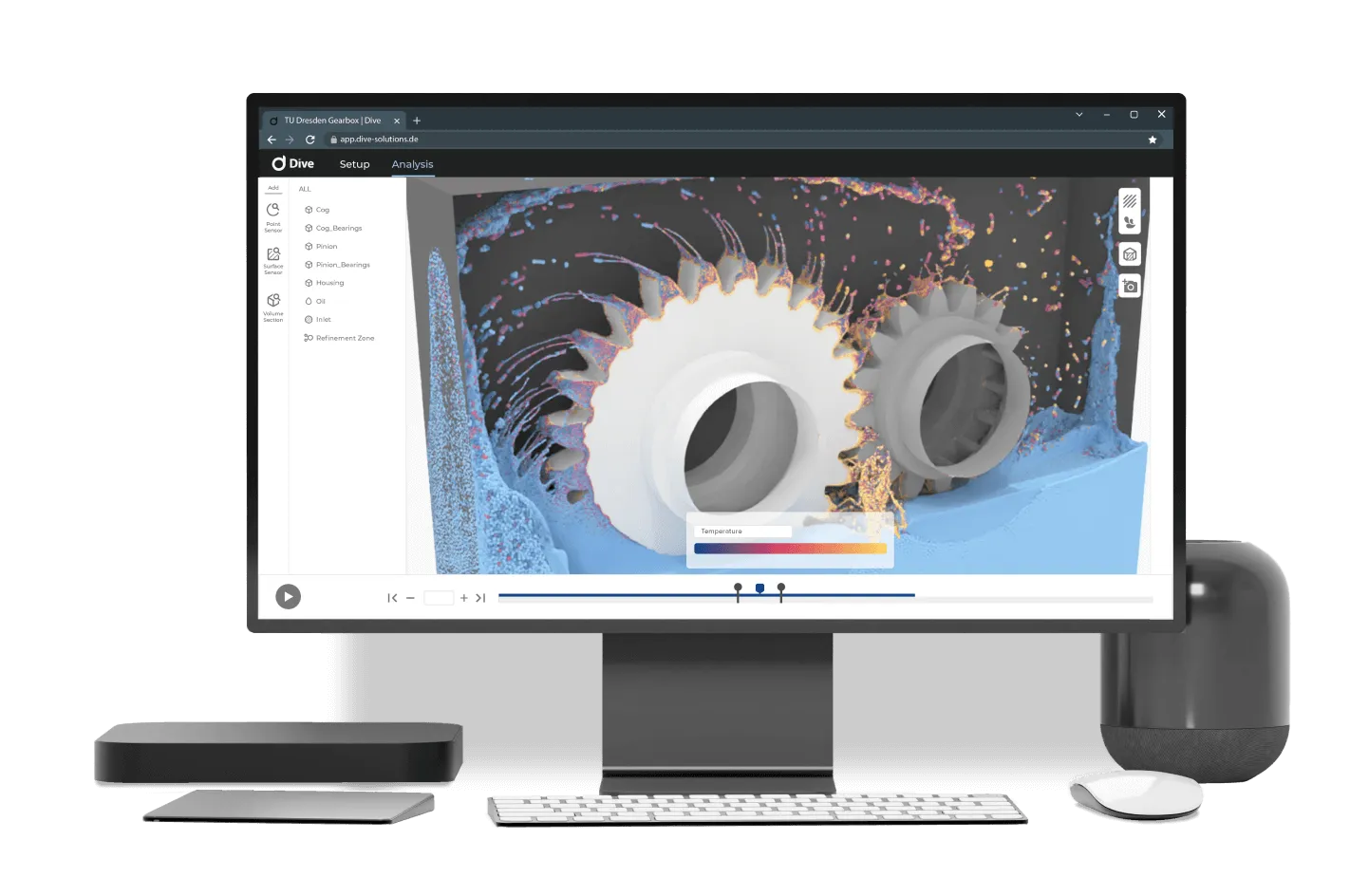

We use a particle-based method called Smoothed Particle Hydrodynamic which is superior when it comes to simulating complex moving parts since it’s mesh-free.

Imagine each particle carrying some properties, like speed and density. These particles then move around and exchange information with nearby particles, allowing the simulation to capture complex fluid behaviors, like splashing or swirling, in a more natural way.

We wrote an easy-to-read article explaining the method.

Feel free to schedule a no-obligation demo with us. We'll reach out to discuss your specific needs and determine if our simulation method is the right fit for your problems. If it is, you can participate in a trial to test your case using our tool. Throughout the trial, our Customer Success Engineer will provide support. Once we find the best package for your team, we'll send over the contract for you to sign.

After signing the contract, you'll receive your initial admin login. From that point on, you can start simulating and obtain results within a few hours. There's no installation or account setup required. To invite additional users, simply provide their email addresses.

Here comes the power of cloud-based platforms. Collaborate seamlessly with all engineers in your department using a single online tool, regardless of their location. With just one license, there's no need to reserve tool slots anymore. Simply log in and start collaborating whenever you need.

A Dive representative will contact you, typically within 1 business day. Note: Only registrants with valid use cases will be contacted.