Industrial Gearboxes

Automotive Gearboxes

Marine Gearboxes

Aviation Gearboxes

Roller Bearings

Sufficient and reliable oil supply is essential in order to avoid gear and bearing damage under various operating conditions. The aim is to create a thin oil layer separating two components, thus minimizing wear, friction, and excessive heat generation.

The thermal management of the component is equally important for a long-lasting component. Furthermore, the lubricant’s additives play many different roles, ranging from corrosion inhibitor to antifoam to reliable abrasion setting.

Ensuring that all components are wetted properly is key, and it is critical to know early in your design process which regions are not sophistically lubricated. This should be known before you’ve built or even shipped your product. Why?

Your most precious resource is time. Minimize lost time by frontloading your development process with digital solutions. Frontloading also saves money, as we all know what a recall campaign of a whole gearbox series costs.

Active lubrication is an excellent method to precisely adjust the oil supply to the areas where it is required and avoid the costly churning of your high-speed gears through an oil bath. But which nozzles should you use to optimize the oil jet impingement on the gear teeth surface?

Shall I use a solid stream, full cone or flat fan nozzle? And, is it even worth it to install the oil-pump or is a bath lubrication the most beneficial option after all?

General guidelines are acceptable, and your internal knowledge is sophisticated, but this topic becomes relevant every time you develop a new application, so evaluating these design possibilities beforehand will foster your strategic advantage in the market.

It’s no secret that mechanical components last longer if they stay cool. But the story is more diverse for gearboxes: The mechanical engine power is partially converted into heat while being transformed at the gear stages – components become hotter, and their structure becomes weaker. How to transport this heat to the ambience? With the lubricant! Easy, right?

But we all know that too much oil only leads to more issues: a blocked breather might reduce ventilation cooling, the cold start may not work as planned, or the lubricant properties may change drastically with higher or lower temperatures, causing the lubrication functionality to fail. Temperature effects are complex, and a reliable monitoring tool is essential.

Bearings are the unnoticed stars in transmissions, always supporting the shafts by carrying axial and radial loads. Their durability and functionality must be reliable in all operating conditions. A major challenges for bearing lubrication is that many small surfaces are always in contact with the inner and outer rings. Analyzing the smallest fluid scales is critical and can be done effectively with particle-based fluid simulation. Read our Success Story with Schaeffler, where we explain the challenges of simulating roller bearing lubrication.

Transmissions distribute excessive loads within your machinery by converting momentum and rotational speed to the desired ratio. For all mechanical systems, these processes come with unwanted heat generation due to the friction within the highly loaded contacting components, the squeezing of the lubricant in between the contact zones, and the splashing of the lubricant-air mixture inside the gearbox.

Again, sufficient oil supply is critical, but an oversupply results in excessive losses. Progressive mechanical engineering designs target the highest possible energy efficiency and raw material sustainability, rendering conservative approaches as obsolete.

Especially for situations where rotational speed is high and load is low (like driving on the highway in the top gear), powering the lubricant’s motion becomes prominent in the power balance. The first step is to understand how much power is required, the next is to analyze it by component, and the last is to optimize the loss distribution on a component level.

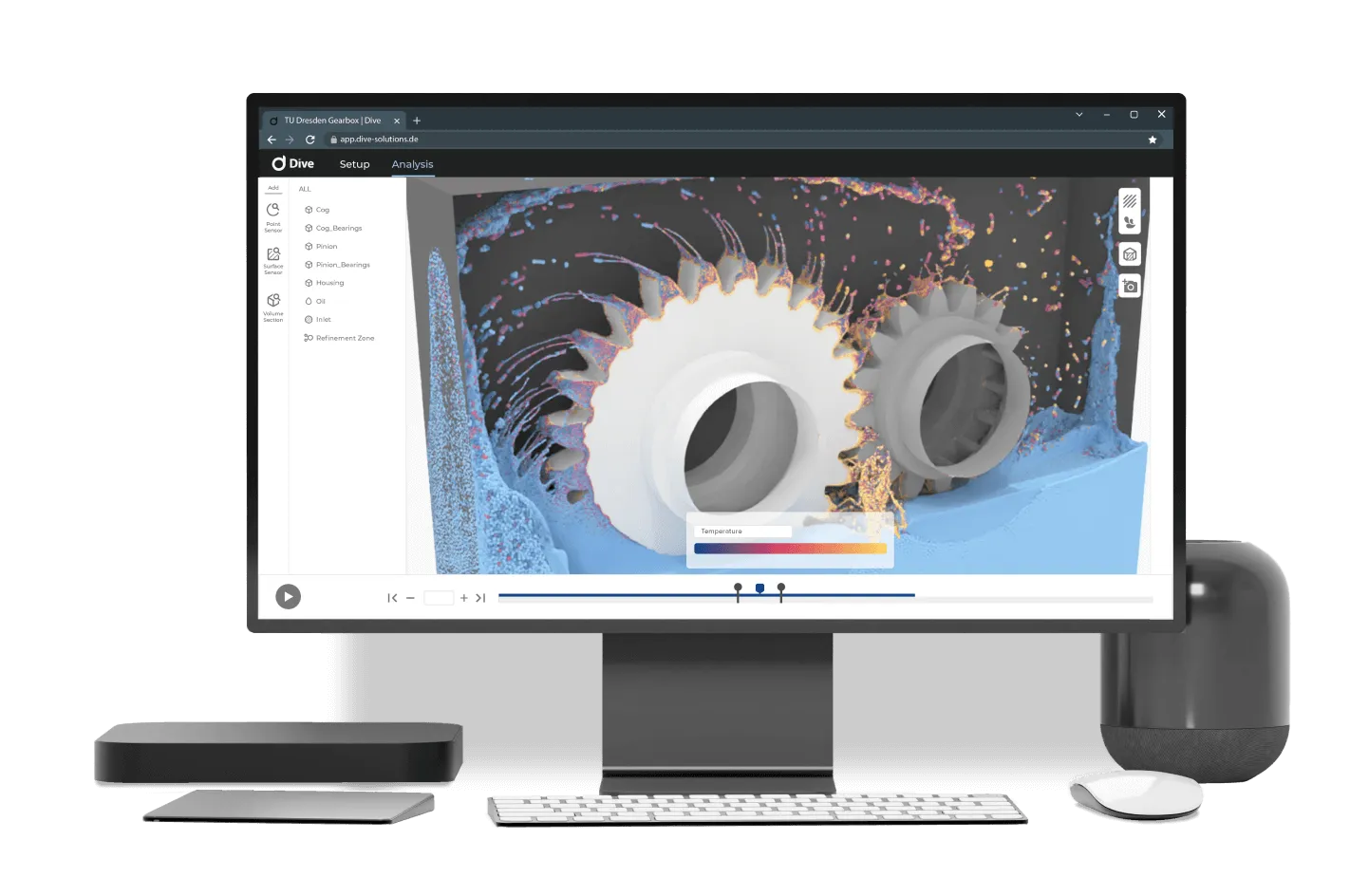

Determining total churning losses and the loss distribution for each component may be difficult or impossible with experiments, but it is all possible with particle-based fluid simulation. You can read how it was achieved for the TU Dresden Gearbox in one of our articles here.

We use the integral boundary approach which works directly with the triangle surface mesh. This makes it possible to accurately represent the gears and the meshing zone. Look at the video showing how easy it is to upload a standard STL file and set the movements. On top of that, you can use Python script to automate the process. Thanks to the triangle-based boundary conditions, results are highly accurate. Accurate geometry means better results.

The rule of thumb is that windage phenomena becomes prominent at around 20(25) m/s pitch line velocity. At this velocity, it is necessary to use simulation in order to optimize your lubrication. Why is that so?

First, larger inertia of the oil phase during the gear rotation leads to the oil being thrown of radially and, second, an air cushion is formed in between gears teeth. With the air shielding the gear, oil in the bath as well as airborne oil droplets are deflected.

Our sophisticated multiphase approach has you covered whenever you analyze these situations.

Multiphase flows can be simulated in just a few clicks, as shown in this example video. Just add air as a second filling, move the seed point to desired space and that's it. If you want to see particles, click discretize.

Have a look at how the oil is mixing with the air and compare with your single-phase results!

Selecting the correct gear set for your application, defining the housing geometry, choosing the material and surface finishes. These are costly and critical parts of your work, and the final designs vary a lot! What do they all have in common? A lubrication system! The advantage of CFD? It gives you the power to analyze every lubrication system independent of the chosen gear set.

Spur gears, helical gears, bevel gears, epicyclic gears, worm gears: the list goes on! Even complex setups can be analyzed through various interfaces.

Is dipping the gears into the oil sump not satisfying your needs? You can create a solid stream with a full cone or flat fan nozzle and even simulate moving oil nozzles.

What about other influential parameters like varying RPMs, low and high temperatures, thin and thick oils, too much or too little oil? These can all be defined within our tool.

Surface tension without artificial tuning parameters to calculate effects like capillary effects in gaps and droplet formation

Complex moving and stationary components to simulate geometrically complex parts including windings

Wetting to analyze where the fluid reaches and where not

Heat transfer to improve cooling concepts, e.g. modern direct oil cooling concepts

Free flow of open-surface fluid flow to effectively simulate jets and sloshing

Multiphase to analyze the interaction and mixing of multiple fluids with different properties

If your engineering team is dealing with liquids and heat management, chances are this is the right software for you.

Use the Dive CFD software, free for a week, including service by a Customer Success Engineer who will ensure successful results for your project. No strings attached. Comfortably evaluate your project before you commit to a subscription.

A Dive representative will contact you, typically within 1 business day. Note: Only registrants with valid use cases will be contacted.